Production & Quality

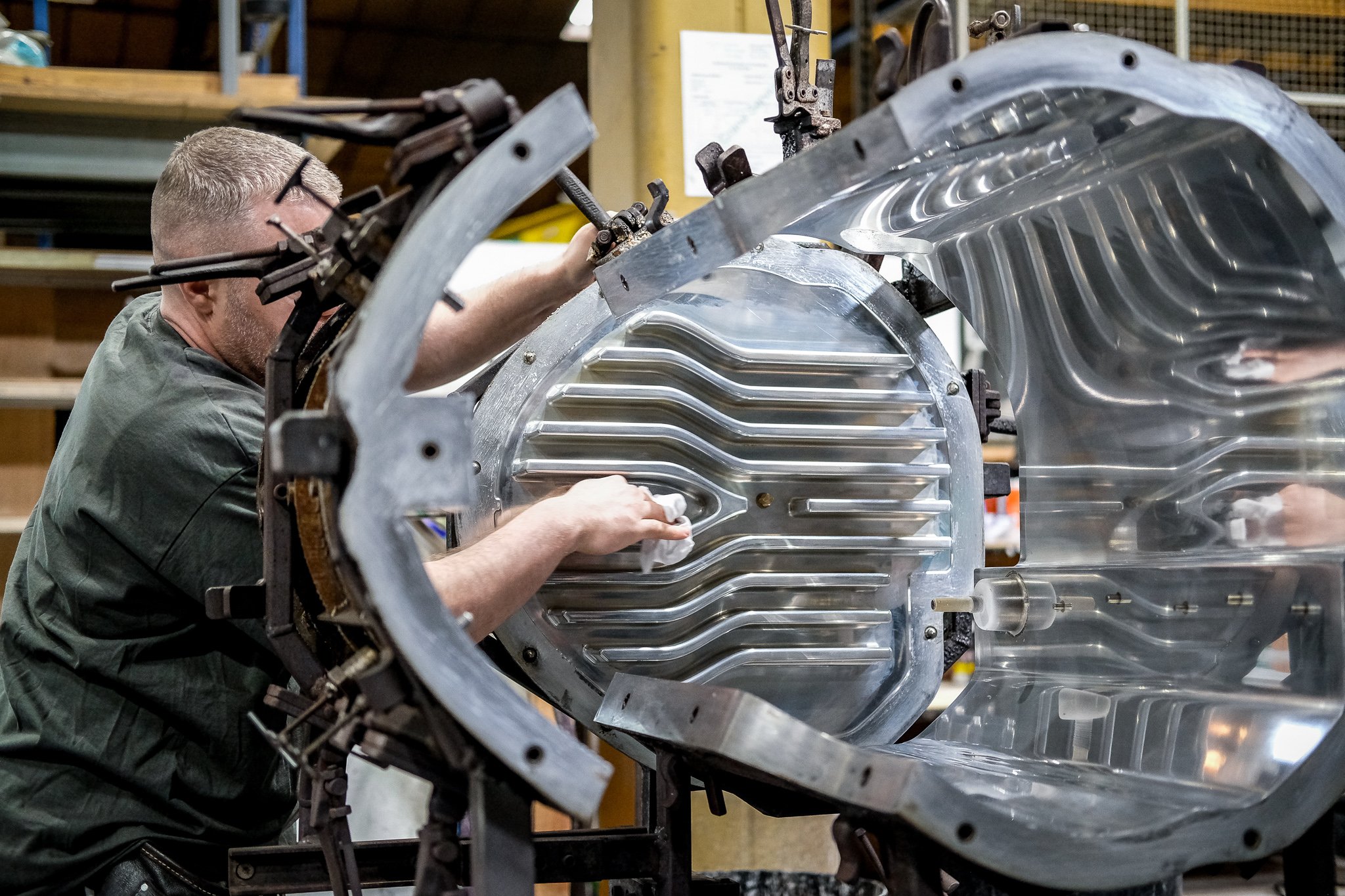

What is Rotational Moulding?

Rotational moulding is a versatile manufacturing process used to create durable, hollow plastic products. Polymer in powder form is placed in a mould, then heated and rotated along both axes to coat the inside of the mould evenly and create a uniform thickness and strength.

At Rototek, we are committed to delivering precision-engineered rotational moulding production solutions that meet the highest quality and efficiency standards. Our approach combines state-of-the-art technology with a strong attention to detail, ensuring we meet your exact specifications. We have over 150,000 square feet of production space across our 2 sites, and over 20 machines to manufacture your products.

How Rototek Advances Rotational Moulding Technology

At Rototek, we lead the way in advancing rotational moulding production through continuous innovation and expertise. By integrating cutting-edge machinery and carefully refined processes, we enhance the precision, efficiency, and product quality of every project. With a focus on sustainability and forward-thinking practices, Rototek is committed to driving the future of rotational moulding and setting new standards for the industry.

Our Rotational Moulding Production Process

At Rototek, our rotational moulding service involves a four-step process:

Design & Development

We work closely with our clients to transform ideas into high-quality, custom-designed rotational moulded products. Our team of experts collaborates with you to create bespoke tools and product designs that meet your unique specifications, optimising every design for efficiency, functionality and durability.

Material Selection & Preparation

We carefully select materials to ensure the highest quality in every rotomoulded product. We work with a range of thermoplastics, each with its own unique benefits.

Polyethylene (PE) offers excellent durability and impact resistance, while polypropylene provides chemical resistance for various applications. Nylon can be used for its strength and durability in certain applications.

Moulding Process – Heating, Rotation & Cooling

The rotomoulding process at Rototek involves three key contributors: heating, rotation, and cooling. First, the mould is heated to a precise temperature, causing the plastic material to melt and start coating the inside of the mould. The mould is rotated along both axes to ensure even distribution across all surfaces. Finally, the mould is cooled, solidifying the material and allowing the product to be removed.

Finishing & Post-Production Services

After the moulding is complete, we trim the product to remove excess material. We also offer component assembly services, transforming your moulded parts into complete, functional products according to your specifications.

We offer additional services, including the installation of custom graphics, leak-testing, thickness measurement, packaging and delivery. Quality control checks are standard to guarantee that every product meets the highest standards.

Quality Assurance in Rotational Moulding

Quality assurance is at the heart of Rototek’s rotational moulding production services.

Quality Control at Every Stage

We undertake rigorous inspections and testing at every stage of the production process. From the tool design and material selection to the final product, we conduct visual inspections, dimensional testing, stress analysis, and more to ensure that every product exceeds both your expectations and industry standards.

Ensuring Durability & Consistency

Our advanced rotational moulding process guarantees consistent material distribution, enhancing strength and durability across every product. Our precision technology and strict quality control procedures ensure that each item is manufactured accurately, providing reliable performance over time, even in the most demanding applications.

Compliance with Industry Standards

At Rototek, we are committed to maintaining the highest quality and safety standards by strictly adhering to UK and international standards. Our rotational moulding production processes comply with relevant industry standards, including ISO 9001 certifications and other quality assurance guidelines. This ensures that we not only meet client specifications but also promote sustainability and regulatory compliance.

Why Choose Rototek for Rotational Moulding?

Clients choose Rototek for their rotational moulding needs for a range of reasons:

Custom Solutions for Diverse Industries

Whether it's agriculture, marine, industrial, construction, or consumer goods, our team specialises in providing bespoke rotational moulding solutions to a wide range of industries. We work closely with clients to design and produce custom-moulded products tailored to their specific needs.

Cutting-Edge Technology & Skilled Expertise

We invest in the latest machinery and cutting-edge technologies to ensure precision and efficiency in every project. This, combined with the expertise of our experienced team, allows us to produce high-quality custom-moulded products.

Frequently Asked Questions (FAQS)

What Materials Can Be Used in Rotational Moulding?

Commonly used materials include polyethylene (widely used for tanks, containers and outdoor products), polypropylene (chemical-resistant parts), and nylon (industrial applications).

How Does Rototek Handle Complex Mould Designs?

Combining our advanced technology and expert design team with production knowledge and experience, we can produce complex rotationally moulded products with high precision and extensive customisation.

What Are the Typical Lead Times for Production?

Lead times vary depending on the size and complexity of the project, but the lead time for tooling ranges from 10-12 weeks.

How Does Rototek Ensure the Durability of Its Moulded Products?

We implement rigorous testing and quality control measures throughout production, including leak testing, thickness checking, dimensional checks and more.

Can Rototek Provide Post-Production Support and Services?

Yes, we offer comprehensive post-production support and services to ensure your product is fully functional and ready for use. These include assembly, finishing and logistics - contact us to learn more.

Trust Rototek for Precision & Quality

With a focus on durability, efficiency and custom solutions, Rototek is a trusted partner for rotational moulding needs across a wide range of sectors.

Commitment to Excellence in Rotational Moulding

At Rototek, we are committed to excellence in every aspect of rotational moulding. From the initial design to the final product, we prioritise quality, precision and innovation in every project, delivering superior products that exceed client expectations.

Looking for high-quality rotational moulding? Contact Rototek today to discuss your project and get a quote.