post-production Assembly & dispatch

POST-PRODUCTION FINISHING & END-TO-END SERVICE

Rototek delivers a comprehensive custom plastic moulding service, extending beyond the moulding process to encompass efficient and reliable post-production assembly and dispatch as part of our end-to-end manufacturing solution. We ensure that your finished plastic components are fully assembled, professionally inspected, and packaged and delivered with the greatest precision and care, ready for immediate use or onward distribution.

Streamline your supply chain and accelerate your speed-to-market with Rototek as an extension of your manufacturing and logistics process, transforming raw materials into finished goods ready for your customers: from design to doorstep. From complex marine components to branded logistics containers, our post-mould assembly services include:

Trimming and de-flashing to your specifications

Component assembly and fitting

Inspection and quality checks at every stage of the process

Packaging – bulk, individual, or custom formats

Global dispatch to your warehouse or direct to your customers.

POST-PRODUCTION ASSEMBLY SERVICES FOR ROTOMOULDED PARTS

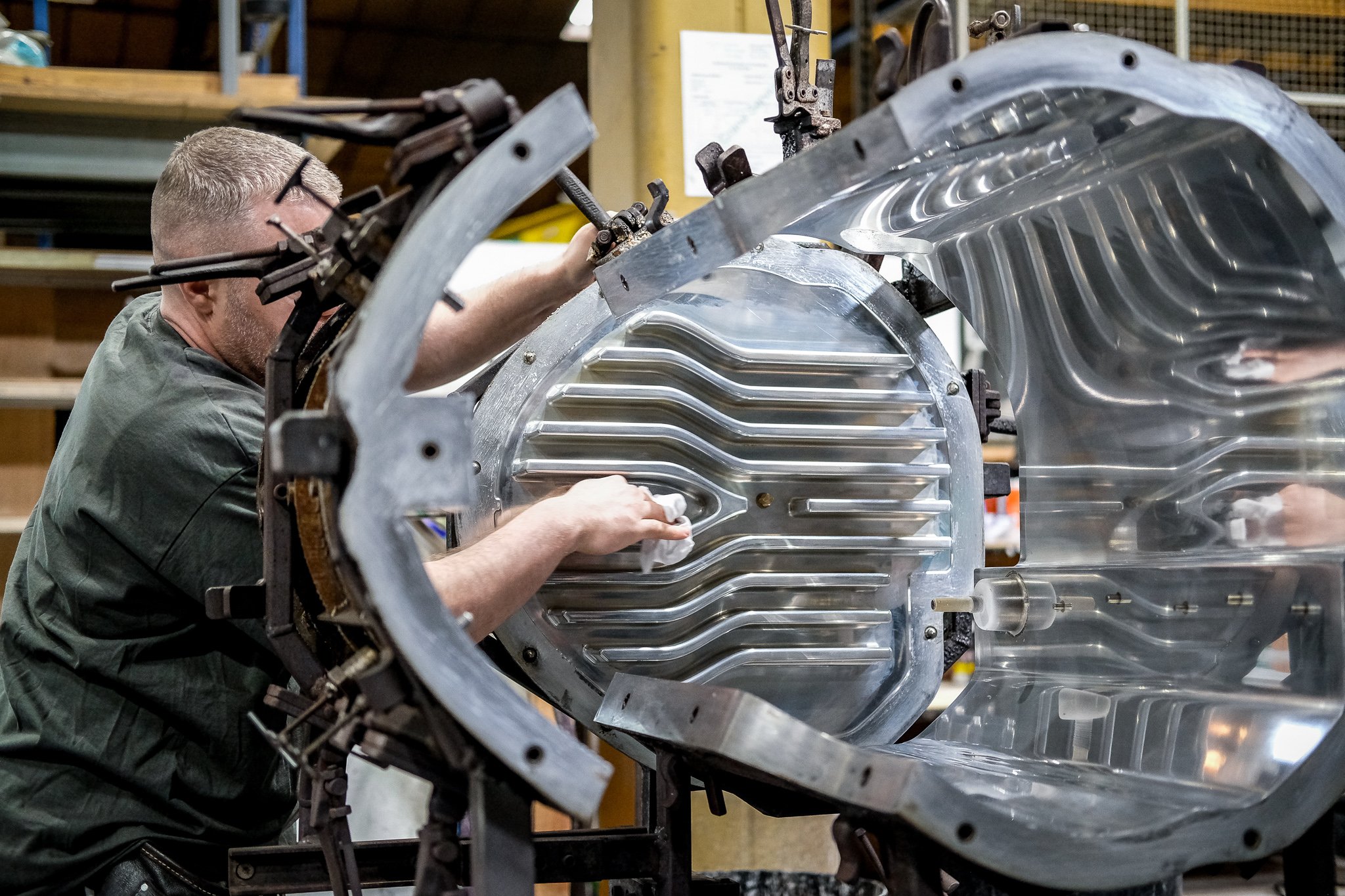

At Rototek, we turn rotationally moulded parts into customer-ready plastic components. Every step is completed in-house, giving you full control, traceability, and quality assurance. After your product leaves the mould, trimming and assembly covers:

Removing mould seams and excess material to achieve clean, precise edges

Drilling, milling, or machining for holes, slots, or openings

Component fitting, including additional fixtures, handles, hinges, valves, or mounts

Decal application and white-label branding.

Fully Finished Products

For clients seeking a hands-off approach, we can deliver custom plastic products fully assembled and ready for deployment. This product finishing service is ideal for OEMs requiring white-label or branded finished goods that can go directly to market or to end-users.

Partial Assembly

If your internal processes require specific final touches and you'd prefer to carry out those elements of the finishing in-house, we can trim and prep the product for post-production assembly and dispatch, allowing you to complete the final stages at your facility.

Every project is different. That’s why our assembly options are adaptable to your operational requirements and end-use case. Whether you need simple trimming and quality checks or fully assembled, market-ready products, our finishing capabilities save you time, reduce your operational overhead, and guarantee consistent quality. With a trained in-house team and robust quality assurance protocols, we help your business get rotomoulded products out of the factory and into your customers’ hands.

BUILT-IN QUALITY AT EVERY STEP

Our post-production assembly and dispatch processes are underpinned by a thorough quality management system and meticulous attention to detail. Every product that leaves our facility undergoes rigorous inspection and sign-off. Our in-house finishing team is specially trained to analyse structural integrity, spot imperfections, ensure the correct fitment of components, and confirm that every product meets both clients’ expectations and our own high standards.

When your reputation depends on the quality of your finished goods, you can depend on Rototek to deliver. In 2024, over 99.4% of our products met or exceeded customer expectations. This performance is a direct result of our investment in skilled people and stringent quality assurance processes. We’re also proud to be ISO 9001 certified and hold B Corp accreditation, committed to both operational excellence and responsible manufacturing practices.

PACKAGING & GLOBAL DISPATCH OPTIONS

Completing our end-to-end rotational moulding service, Rototek also provides packaging and worldwide shipping services, ensuring your moulded plastic products reach their destination securely and on time. Once assembly is finished, along with quality assurance and final finishing, we handle the entire logistics chain, from packaging to delivery anywhere in the world, offering a wide range of shipment options and contract flexibility to suit your business requirements.

Whether you need pallets for large shipments to warehouses and distribution centres or individually packed direct-to-consumer delivery, we safeguard your products against potential damage during handling and transit. Our post-production assembly and dispatch service is designed to make distribution (and even door-to-door fulfilment) simple.

STREAMLINE YOUR SUPPLY CHAIN

At Rototek, we handle production, final assembly, packaging, and global shipment, eliminating the logistical complexity of managing multiple suppliers. We deliver the confidence that every component meets your exact specification, operating in high-demand sectors such as automotive, logistics, construction, marine, and more.

For OEM and procurement leads, working with Rototek means working with a single, integrated supplier, from design through to final delivery, ultimately reducing your internal processing and logistics overheads. When turnaround time and consistency matter, Rototek ensures you get the finished goods you need, where and when you need them, without any bottlenecks.

Component Procurement

We source and manage third-party components on your behalf, saving you the time and complexity of coordinating with multiple suppliers.

Faster Turnaround Times

Consolidating post-moulding services under one roof reduces handovers and improves overall project timelines, enhancing your speed-to-market.

Fewer Suppliers, Less Admin

Working with a single, trusted partner for post-production assembly and dispatch significantly reduces administrative burden and the complexities of supplier management.

WHY CHOOSE ROTOTEK FOR FINISHING & FULFILMENT?

With decades of experience in rotational moulding and the ability to combine rotational moulding, component procurement, assembly, packaging, and logistics, we offer a complete, efficient solution. We are trusted across technical industries to deliver high-spec, high-performance custom plastic products and parts – from fuel tanks to crates, containers, buoys, and bespoke decorative or structural pieces.

From concept to customer, we are your strategic partner in delivering outstanding rotomoulded products to market. Our integrated approach streamlines the entire rotomoulding process, reducing lead times and ensuring consistent quality from moulding to final delivery.

To find out more about how we can help, get in touch - we’d love to hear from you!

If you have any other questions about rotomoulding, feel free to reach out - we’re always happy to talk! In the meantime, answers to some of our most frequently asked questions are below…

How long does the assembly process take?

At Rototek, we strive for efficient turnaround times while maintaining the highest quality standards. Let us know your specific requirements, and our team will provide you with an estimated completion time, tailored to your project.

What does Rototek’s assembly and dispatch service include?

Our service includes trimming, finishing, assembly of additional components, inspection, packaging, and global delivery.

Do you handle third-party components?

Yes. We can procure, store, and fit third-party components as part of our assembly service, ensuring a single point of accountability for your final product.

Frequently Asked Questions (FAQs)

Can you ship directly to my customers?

Absolutely. We offer direct global dispatch services. Whether you're shipping to a warehouse or an end user, we can handle it all, complete with appropriate packaging.

How does Rototek ensure the timely dispatch of moulded plastic parts?

We follow a streamlined workflow for every project to keep production on schedule. The combination of our efficient assembly post-production processes, in-house quality control procedures, and dedicated logistics team ensures that your products are dispatched to reach their destination on time.

Can you ship large plastic products?

Yes. We can handle large, bulky rotomoulded items and even the most challenging dimensions, such as tanks or containers.