Vacuum Forming vs Rotational Moulding

If you're weighing up vacuum forming against rotational moulding for your next project, you're looking at two very different manufacturing approaches. Vacuum forming is quick and cost-effective for simple shapes. Rotomoulding handles complex, hollow parts that need strength, durability, and a seamless finish.

THE VACUUM FORMING PROCESS

Vacuum forming is a relatively quick and straightforward thermoforming technique: a heated plastic sheet is stretched over a mould and sucked down into shape with vacuum pressure. It’s ideal for single-sided items like trays, panels, or display units (typically open-faced or shallow parts). Think simple curves, open shells, and prototypes that need to get to market fast.

ROTATIONAL MOULDING

Rotomoulding is a straightforward process for making strong, hollow plastic parts. We place a plastic polymer powder inside a hollow mould, which is simultaneously heated and rotated on multiple axes. As the mould spins, the plastic melts and coats the inside of the mould evenly. This creates seamless, hollow parts with a consistent wall thickness – perfect for things like tanks, playground equipment, bins, and other large, durable items. Afterwards, the mould is cooled and the finished part is removed. It’s slower than vacuum forming but much more versatile for certain shapes and sizes.

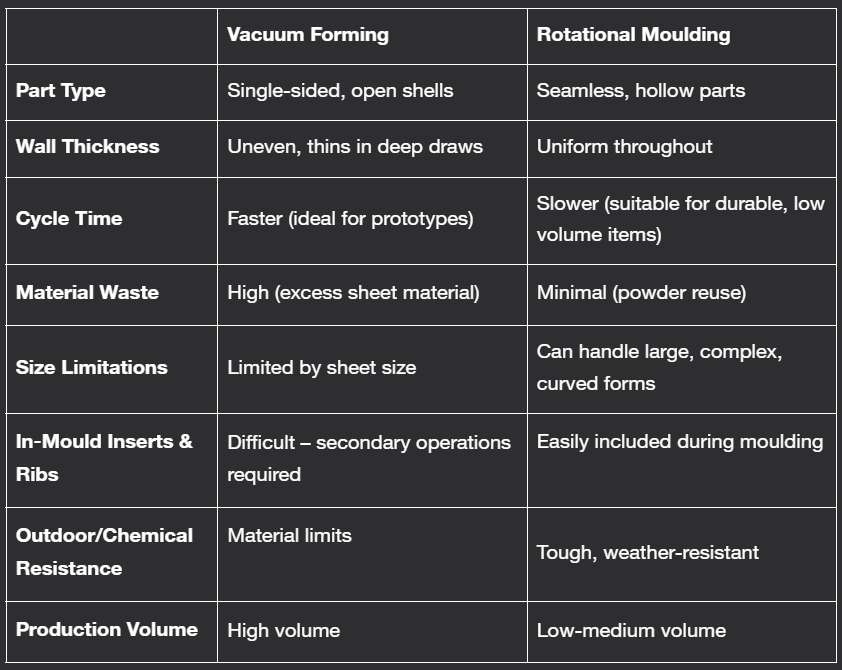

KEY DIFFERENCES BETWEEN VACUUM FORMING & ROTATIONAL MOULDING

If you want a thin, open shell, vacuum forming can do that quickly and cheaply. But if you need a hollow, seamless product with uniform wall thickness, undercuts, ribs, or inserts moulded in, the rotomoulding process is ideal.

SPEED & TOOLING COSTS

Vacuum forming is generally quicker for prototypes and short runs, with lower-cost tooling made from lightweight materials (wood, composite, or aluminum). You can get parts in days rather than weeks, making it ideal for rapid design iteration, although finishing may be required. Rotational moulding takes longer per cycle but keeps tooling costs low for large, hollow parts, making it good value for durable, low-to-medium-volume production.

Rotomoulding requires longer cycle times and higher upfront tooling investment, using fabricated steel, cast or CNC aluminium moulds, but the superior strength and performance of rotomoulded parts often justify the longer cycle times. When you need structural strength, built-in inserts, or high durability, rotational moulding can work out more economical over the life of the product. Tooling is still relatively low-cost compared to other methods, and you get more functionality in each part – which means less finishing, less assembly, and less waste.

DESIGN COMPLEXITy

Vacuum forming is best suited for simple, open-faced, and shallow shapes, as complex details often require additional trimming or assembly. Complex undercuts, sharp edges, or deep features often need secondary processing. Rotational moulding handles more complex, enclosed shapes – including curves, ribs, internal supports, and moulded-in inserts – all in one seamless piece.

WALL THICKNESS & CONSISTENCY

In vacuum forming, plastic sheets are stretched over a mould, so walls can thin out unevenly in deep sections or corners, creating weak points that affect structural performance. With rotomoulding, the plastic powder distributes evenly during rotation, resulting in uniform wall thickness throughout the entire part. This eliminates stress concentration points (which improves structural integrity and performance under load).

DURABILITY

Vacuum-formed parts tend to be thinner, lighter, and less robust, which can limit their lifespan in harsh conditions. They tend to be suitable for shorter-lifecycle applications or protected environments. Rotational moulded parts are thicker, stronger, UV stable, and more resistant to impact, chemicals, and weather, making them a better choice for outdoor, industrial, or heavy-duty use that requires a longer service life.

MATERIAL OPTIONS

Vacuum forming is limited to thermoplastic sheets, typically made of ABS, polystyrene, or PETG. Rotational moulding works with a wider range of materials in powder form, including polyethylene, PVC, polypropylene, and nylon. These materials often offer better chemical resistance and durability for demanding applications.

A SIDE-BY-SIDE COMPARISON

VACUUM FORMING VS. ROTATIONAL MOULDING: WHICH PRODUCTS SUIT EACH PROCESS?

Vacuum forming works best for:

Packaging trays and containers

Kiosk fascias and display panels

Interior automotive trim pieces

Shallow formed parts with simple geometries

Lightweight prototypes requiring quick turnaround.

Rotational moulding is better suited for:

Large tanks and containers (up to 20,000 litres)

Playground equipment and outdoor furniture (e.g. slides, climbing frames, sandpits, ride-on toys, planters)

Kayaks, canoes, pontoons, and buoys

Industrial bins, crates, pallets, and trolleys

Agricultural vehicles, fuel tanks and large components (e.g. ducting, mudguards, dashboard housing)

Medical equipment

Bins and storage containers.

A common misconception is that rotational moulding is too slow. True, cycle times are longer, but you get seamless, robust parts with more complex features that vacuum forming can’t create without post-processing. If you need a plastic part that’s hollow, seamless, tough, and durable, rotational moulding is your answer. Vacuum forming is limited to thin-walled, single-sided moulds.

WHEN TO CHOOSE ROTATIONAL MOULDING OVER VACUUM FORMING

Choose rotational moulding when you need:

Hollow, seamless parts that hold liquids (leak-proof)

Consistent wall thickness for strength and structural integrity.

Complex shapes with integrated undercuts, internal ribs, threads, or inserts.

Tough, weatherproof, chemical-resistant materials.

Long-lasting products for outdoor, marine, industrial or medical use.

Rotational moulding delivers the structural integrity and design flexibility that demanding applications require. For everything else – quick, shallow shells, display panels, or prototypes – vacuum forming might be the answer.

TALK TO OUR TEAM ABOUT YOUR PROJECT

Choosing between the vacuum forming process and rotational moulding isn’t always clear-cut. It depends on your design, volume, budget, and what your product needs to do out in the real world. Still not sure which process suits your needs? Our team has decades of experience helping companies choose the right manufacturing approach for their specific applications. Whether you're developing a new product or looking to improve an existing one, we'll work with you to understand your requirements and recommend the best approach. Get in touch today to discuss your next project.